Friction Drilling and Bike Wheels

Nov 03 2015 0 Comments

The last couple of blogs have been light-hearted, so here's something this week for those of you that drill holes...!

If you are drilling holes through metal, you normally dial the speed down on your drill or drill press, compared to what you'd set it at to put holes in wood. That's because with a twist bit, the heat generated by metal-on-metal friction can dull the bit and result in poor cutting quality.

But an alternative metal drilling process is friction drilling, form drilling, flow drilling or thermal drilling, where the process uses a conical bit spinning at high speeds, and applied with high pressure that relies on friction itself to bore through the material as per video link below:

https://www.youtube.com/watch?v=VzCBQh8B_RY

The extra material displaced by the bit provides more surface area to tap, resulting in more material for a fastener to bite into. It also removes the need to insert a bushing or fix a weld nut, reducing production time and materials. The process does not produce shavings, meaning the operator does not have to spend time cleaning the work area. Just drill, tap and fasten.

And here's a little bit of history: Friction drilling is not a new technique; it was first dreamt up in the 1920's, around the same time the high-heat-withstanding cemented carbide necessary to produce the bit was developed. It is used in bicycle frames, and companies like France's Mavic uses friction drilling to produce their Ksyrium wheels, creating rims that the spoke nipples thread directly into. The guy in this video below reckons the process makes their wheels 20% more rigid and increases their resistance to fatigue stress by a factor of four:

https://www.youtube.com/watch?v=kLQr6E7lGrQ&feature=youtu.be

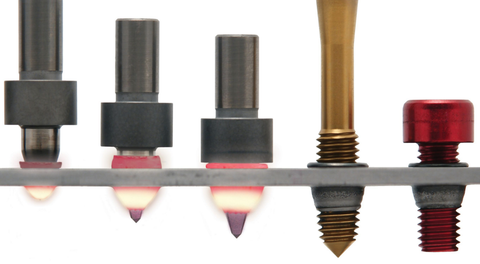

For applications where the rolled collar produced on the surface is not desirable, bits with cutting surfaces located above the cone (shown below) exist. After the hole is bored, the extra material up top is trimmed away.

There is also a technique that makes the procedure even faster. Tooling companies like the UK's Quantum use flow drilling screws/bolts, whereby the tip of the screw itself is actually the bit, and the threads further up do the tapping. This means that the drilling, tapping and fastening are all done in a single step (though there's presumably something lost in set-up time):

If you're interested in learning more about friction drilling, just click either of these link's:

http://www.formdrill.com/english/formdrill.htm

http://www.trick-tools.com/Flowdrill_760?view_all

Cheers, Gaston

0 comments

Leave a Comment